Silicon Material And Silicon Wafer Solutions

There will be many serious problems in solar cell production proces, a variety of problems such as resistivity, minority carrier lifetime, dislocations, impurities, debris, cracked, black heart surface, contamination, etc., it is these defects limit photoelectric conversion efficiency and service life of the solar cell. Also, because there is no perfect industry standard, silicon and silicon quality is uneven, some defects in the presence of a direct impact on the cell and even the stability of the photovoltaic system. Therefore, the solar industry needs fast and accurate positioning test methods to solve these problems.

Solar Cell And Module Solutions

In recent years, the photovoltaic industry is developing rapidly, especially in mainland China, investment in solar cells are unusually large, thousands of photovoltaic enterprises, production capacity is clearly excessive, other U.S. sanctions against China and the European economic crisis also greatly affected the sales of enterprises development. Consolidation and elimination is the inevitable trend of the industry. Therefore, in order to remain invincible in this critical period, improve the efficiency and reduce production costs has become the target of the entire industry.

Solar Power Plant Solutions

At present, coal, oil and other traditional energy frequent emergency, the environmental pollution problems is increasing seriously. Solar energy as the most promising renewable energy because of its unlimited reserves, the existence of universality, the use of clean and practical economy, more and more conutries invest and develop the PV industry, and become an important part of the national sustainable development strategies. PV power plant from the current run of practical experience, to ensure the security, economic and efficient operation of the photovoltaic power generation system, you must select reliable and stable detection equipment and the establishment of norms and effective management mechanism.

Sapphire And Silicon Carbide Solutions

Quality of the substrate determines the quality and application of whole LED industry, but manufacture process of sapphire and silicon carbide production is one of the bottlenecks that limit the development of the entire industry. Especially in China, the core issue facing the lack of technology and patents. In addition, for the product detection, there is no uniform standard to measure the quality of products. Aiming to establish industry status and reputation, it will inevitably require the enterprises not only have long-term view, but also work hard, every detail of the product analysis, so as to steady and healthy growth.

Consumption And Auxiliary Materials Solutions

Silicon dopant, the seed crystal, silicon nitride, cutting wire, slurry etc. these consumption and auxiliary materials seem inconspicuous, but the effect is significant, small things reflect the great wisdom, small things reflect technological progress. This require us pay attention to choose high quality product. However, what are the criteria of these supplies? How the quality and stability? What about the costs and prices?

Newsletter

- Maintenance Services

- Customer issues within 24 hours to answer, e-mail reply within 24 hours, customer complaints processed within 48 hours, work

- Sapphire Seed Crystal

- Sapphire unique nature determine its widely used, but high-quality sapphire is difficult to get. As we know, sapphire s

- Sapphire Dislocation

- Sapphire surface defects and dislocations seriously affect the quality of crystal growth of subsequent epitaxial layers, thu

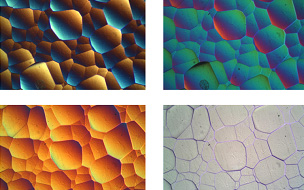

- Application Of Photoluminescence

- PL detection system can monitor all processes in the solar cell manufacturing and gives accurate analysis possibility to the

?2008-2050 HenergySolar. All rights reserved